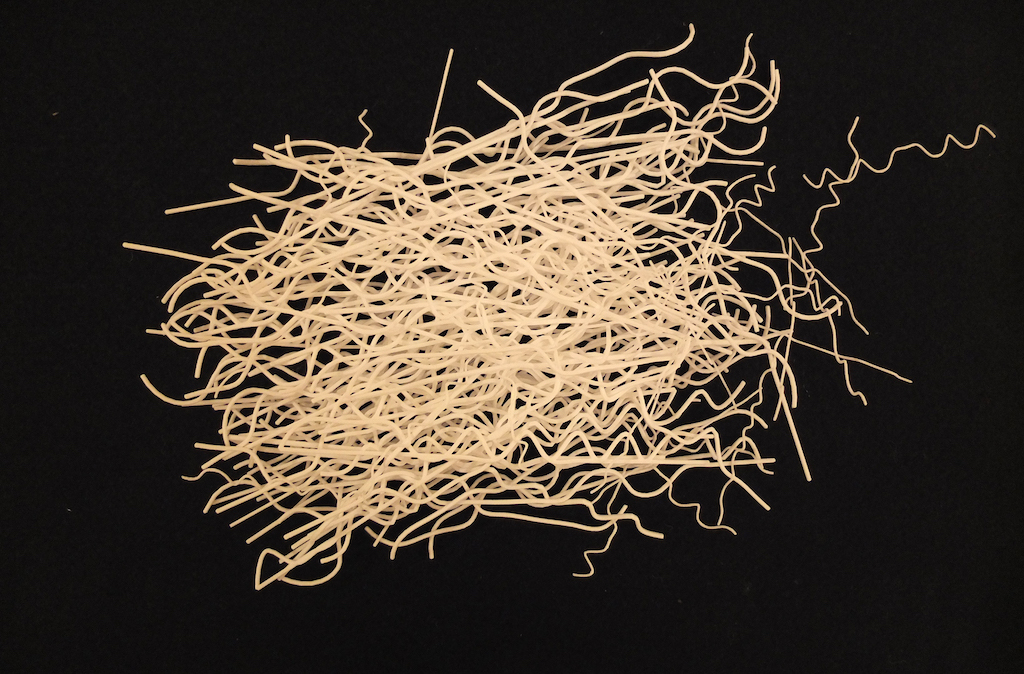

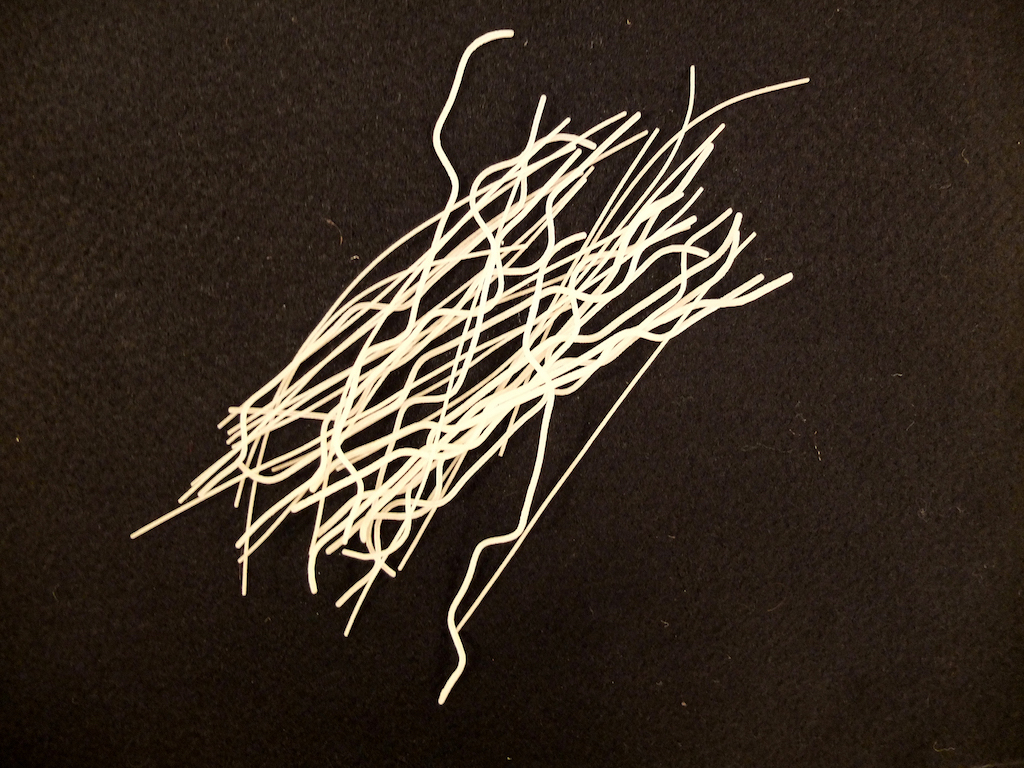

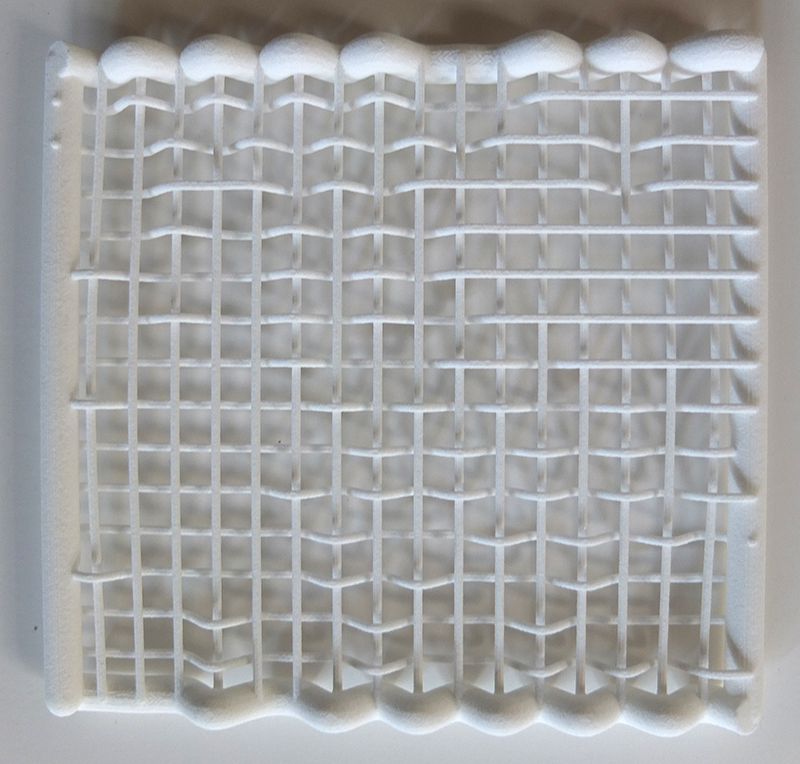

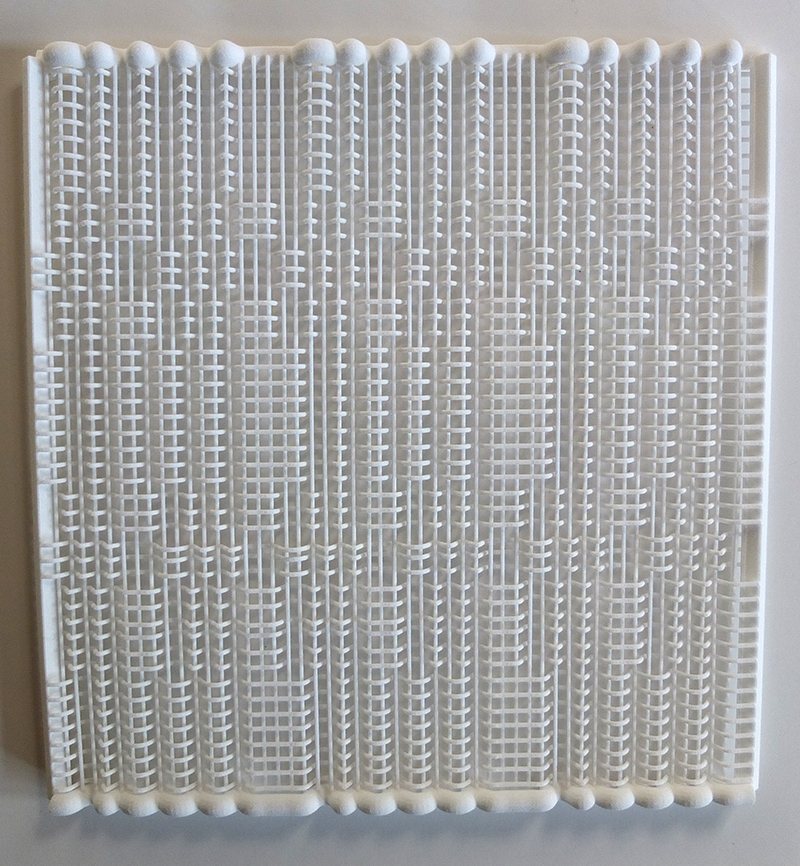

Nylon and Elasto Plastic, 2016

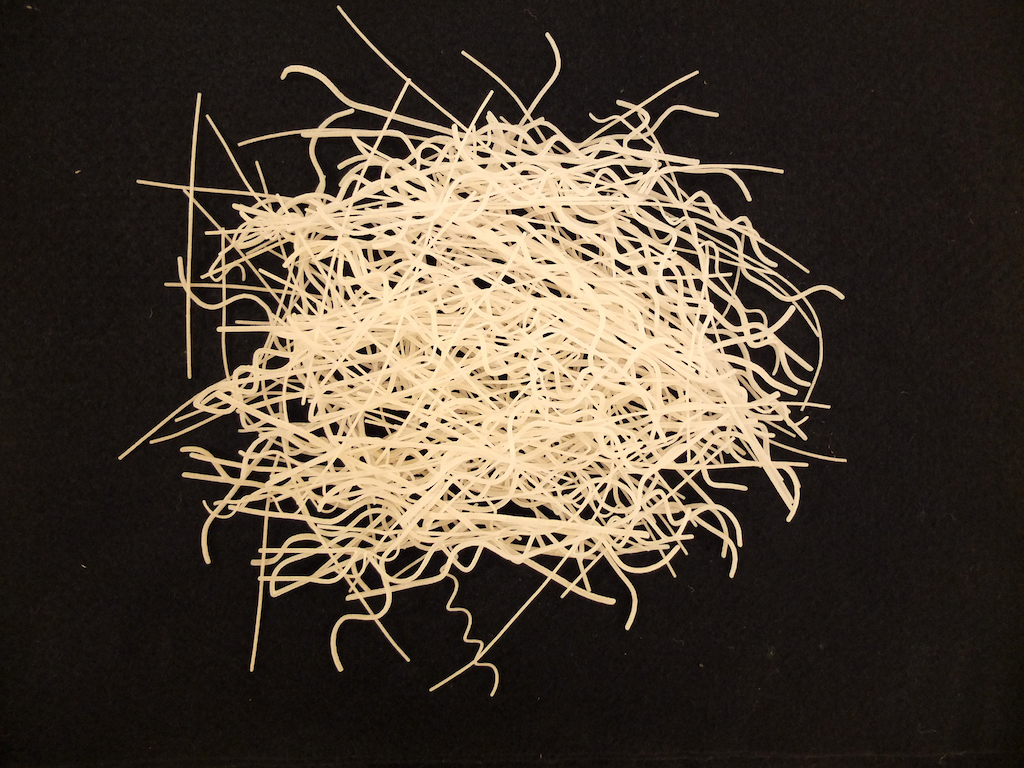

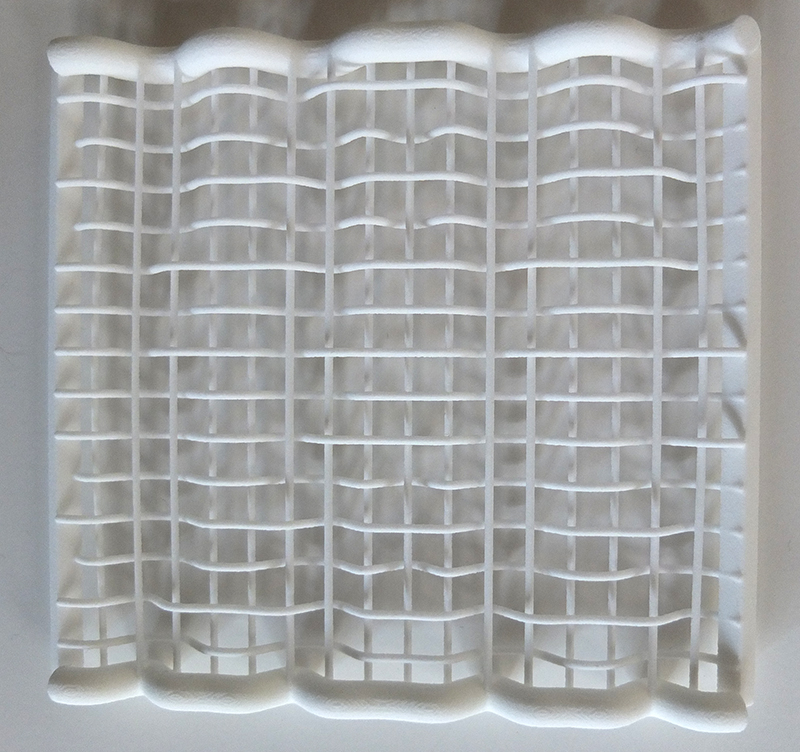

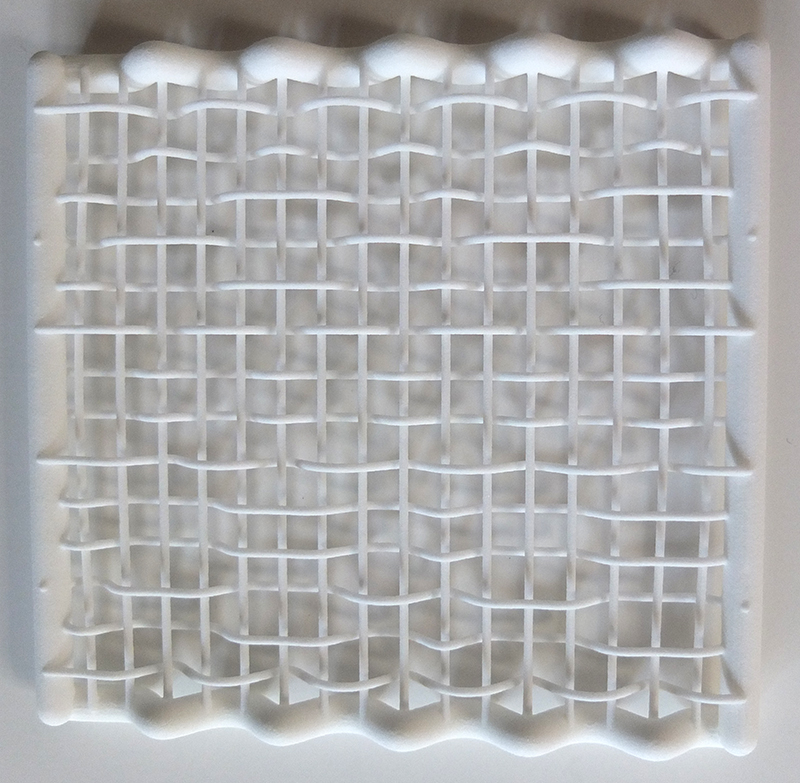

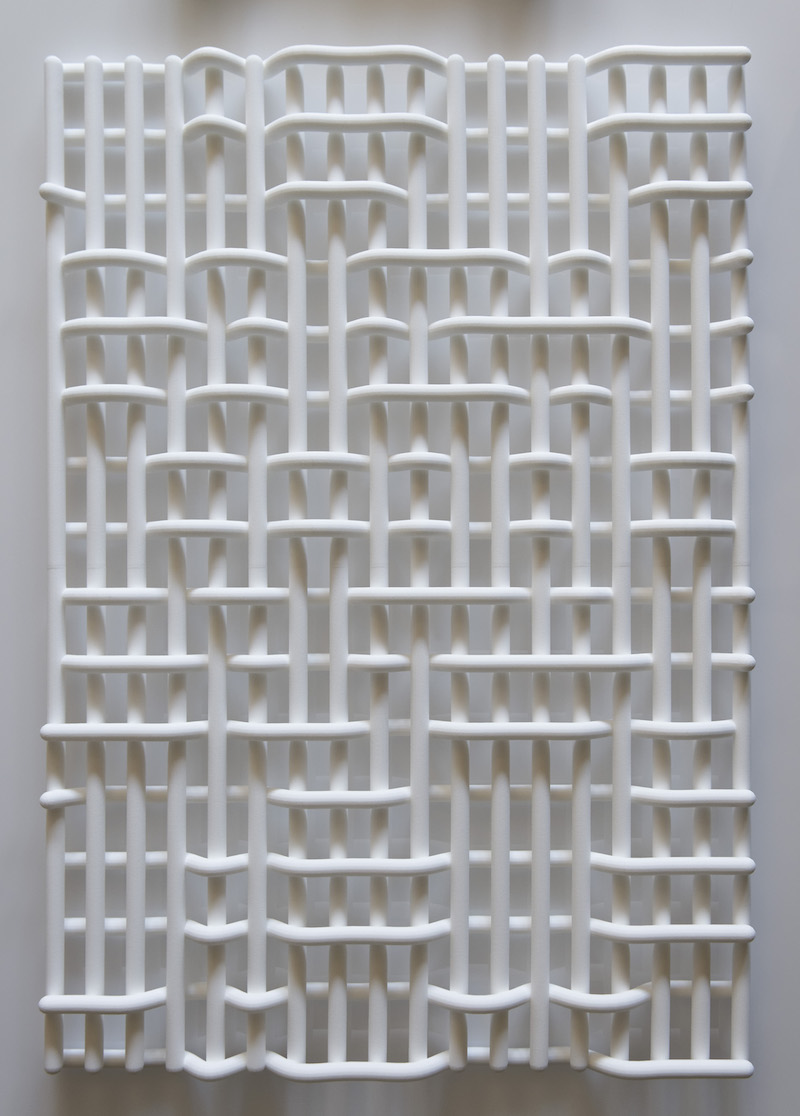

Nylon, 2016

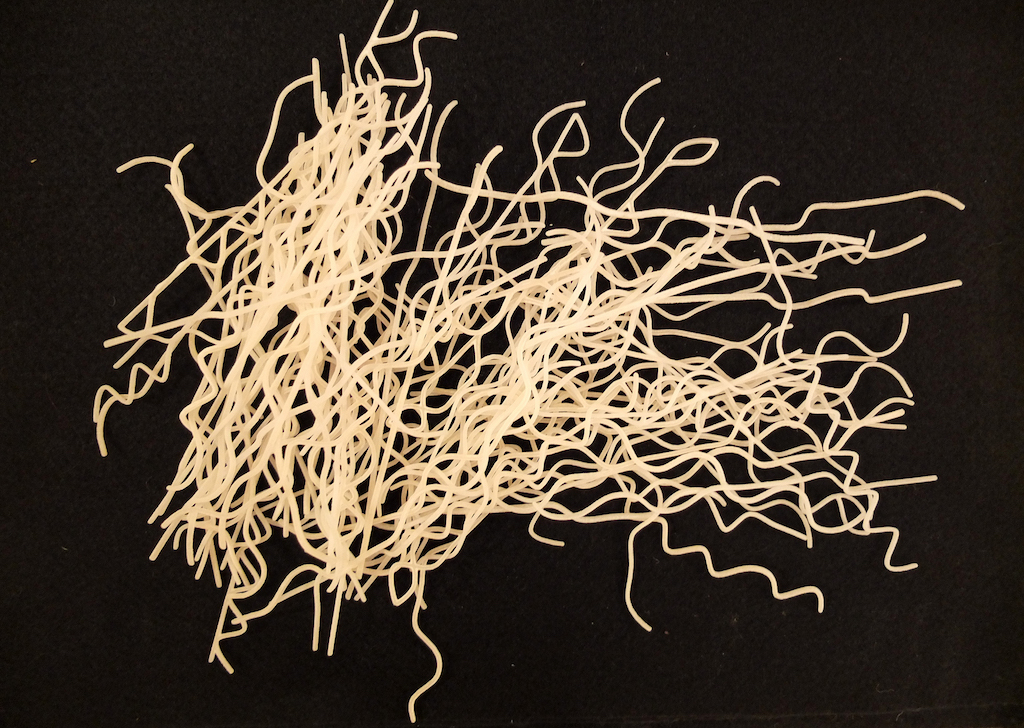

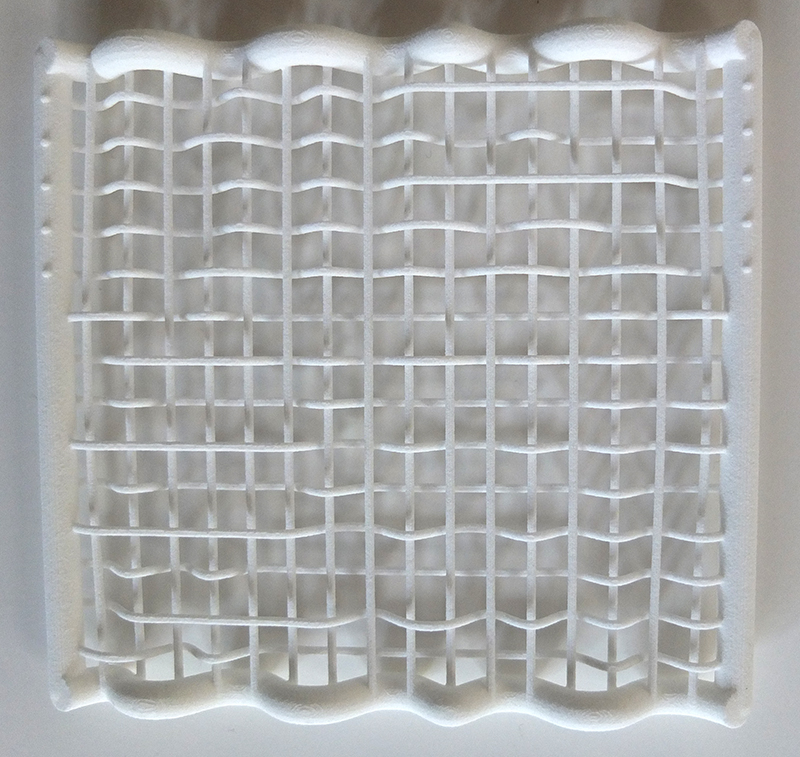

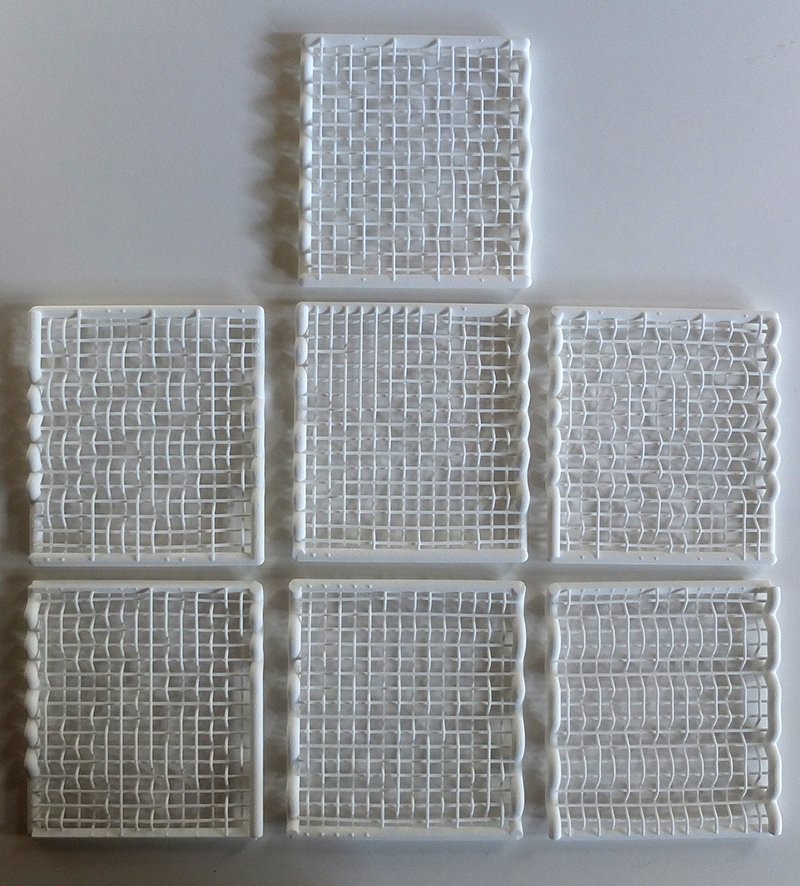

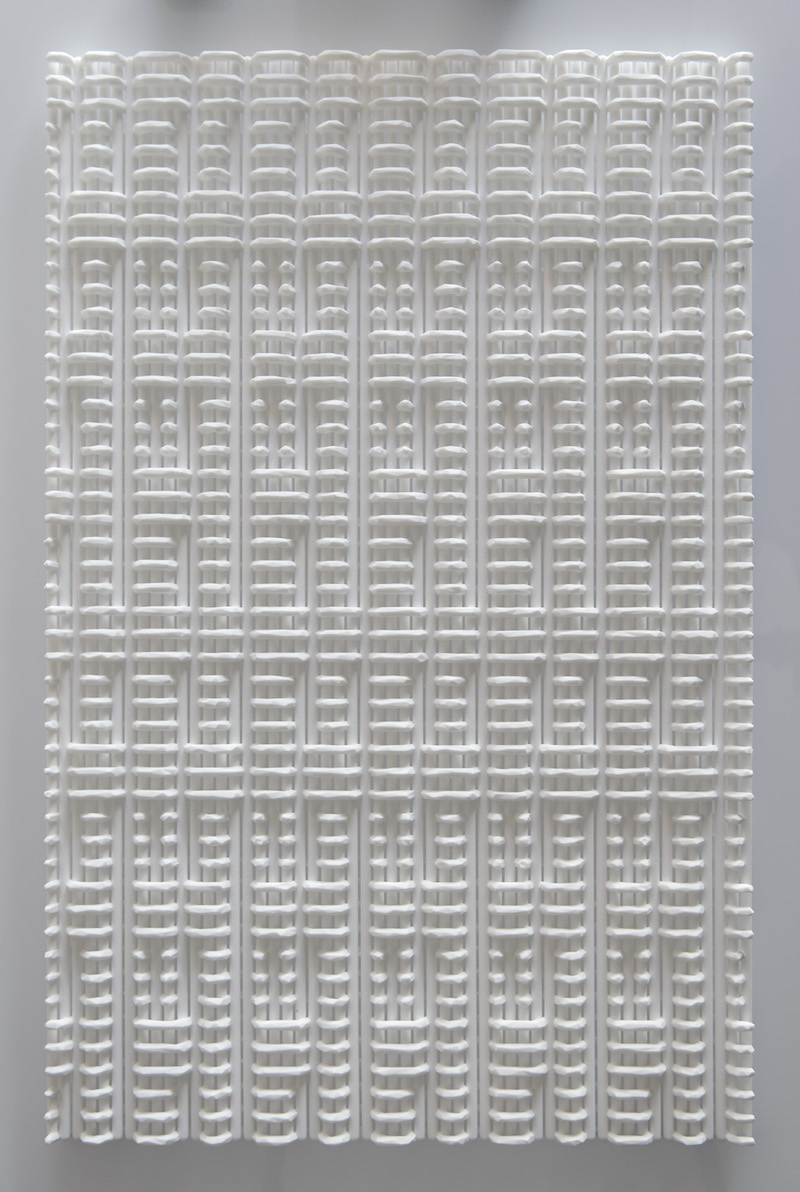

Nylon, 2016

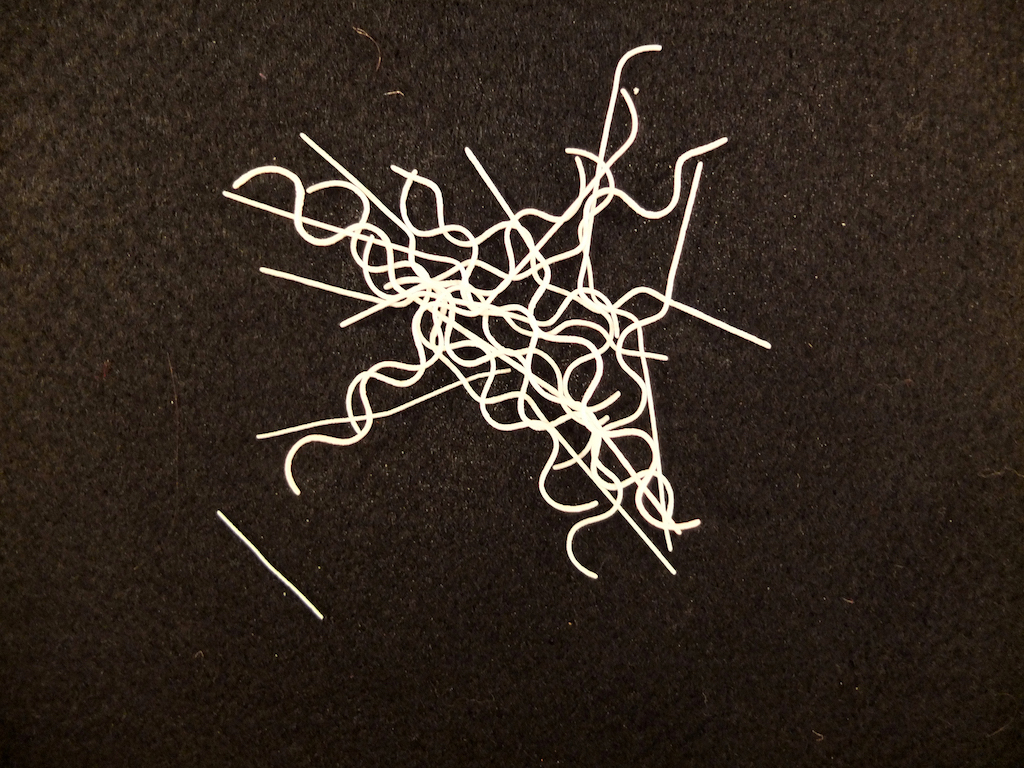

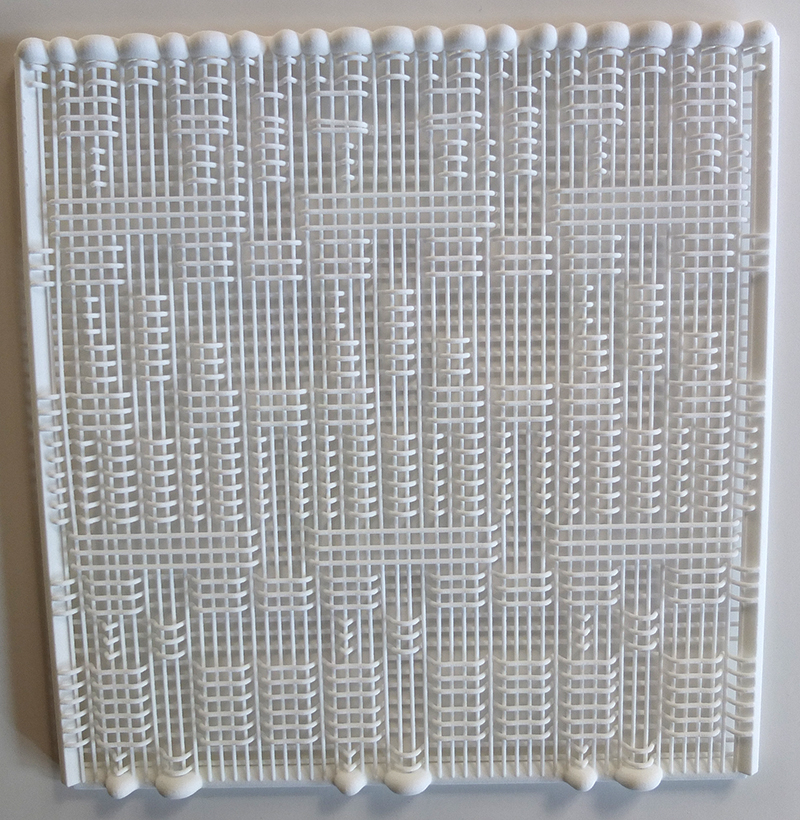

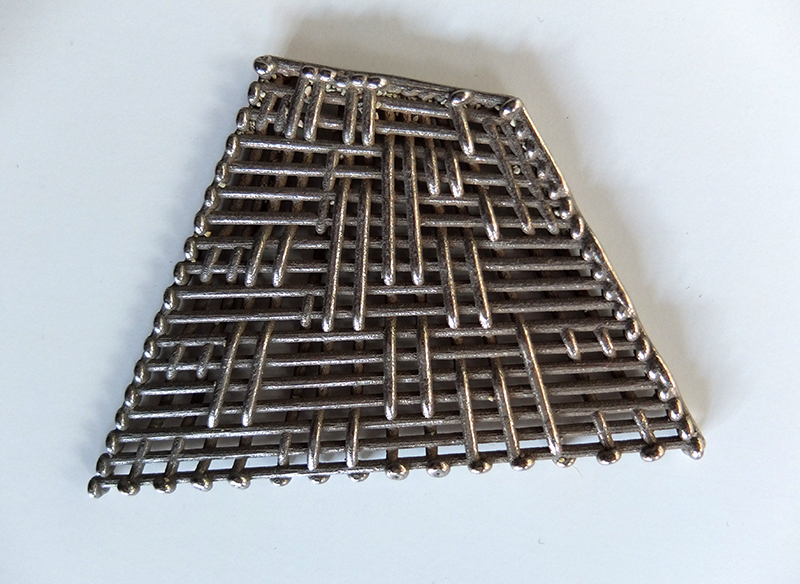

Stainless Steel, 2016

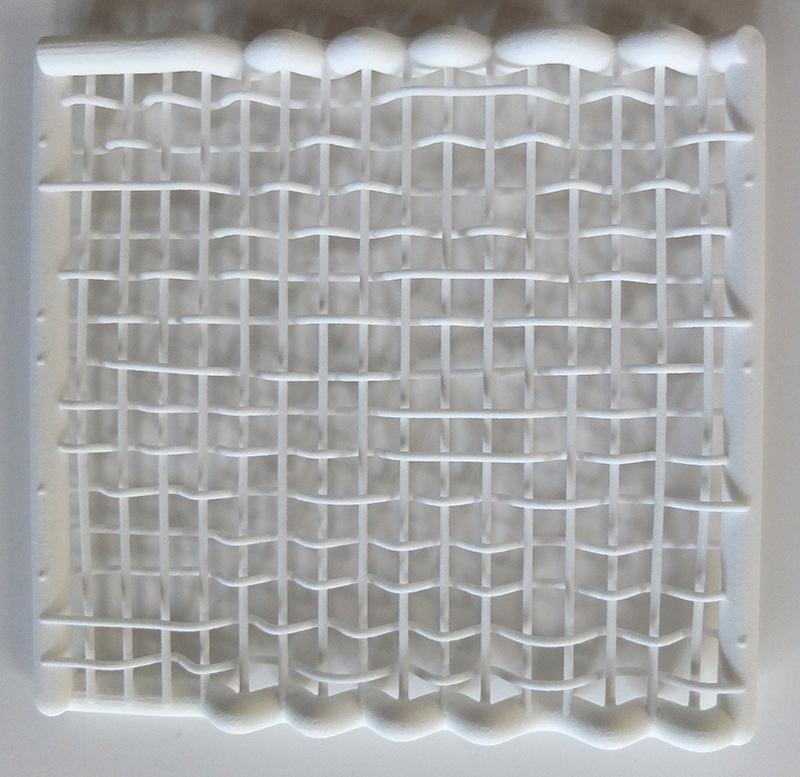

Nylon, 2016

The fashion world has been looking at 3D printing to change the industry. Because 3D printing is like knitting: it uses a single filament, and the construction of the fabric (surface) and shaping of the garment (object) happen at the same time. You have less waste, which is a huge problem in clothing construction. Currently, 3D printing in fashion has only been used to very speculative, conceptual, couture, sculptural clothing. Or gimmicks. The focus needs to shift away from that into the creation of textiles you’d be able to, and want to, wear. Otherwise, cotton gets the job done fine.

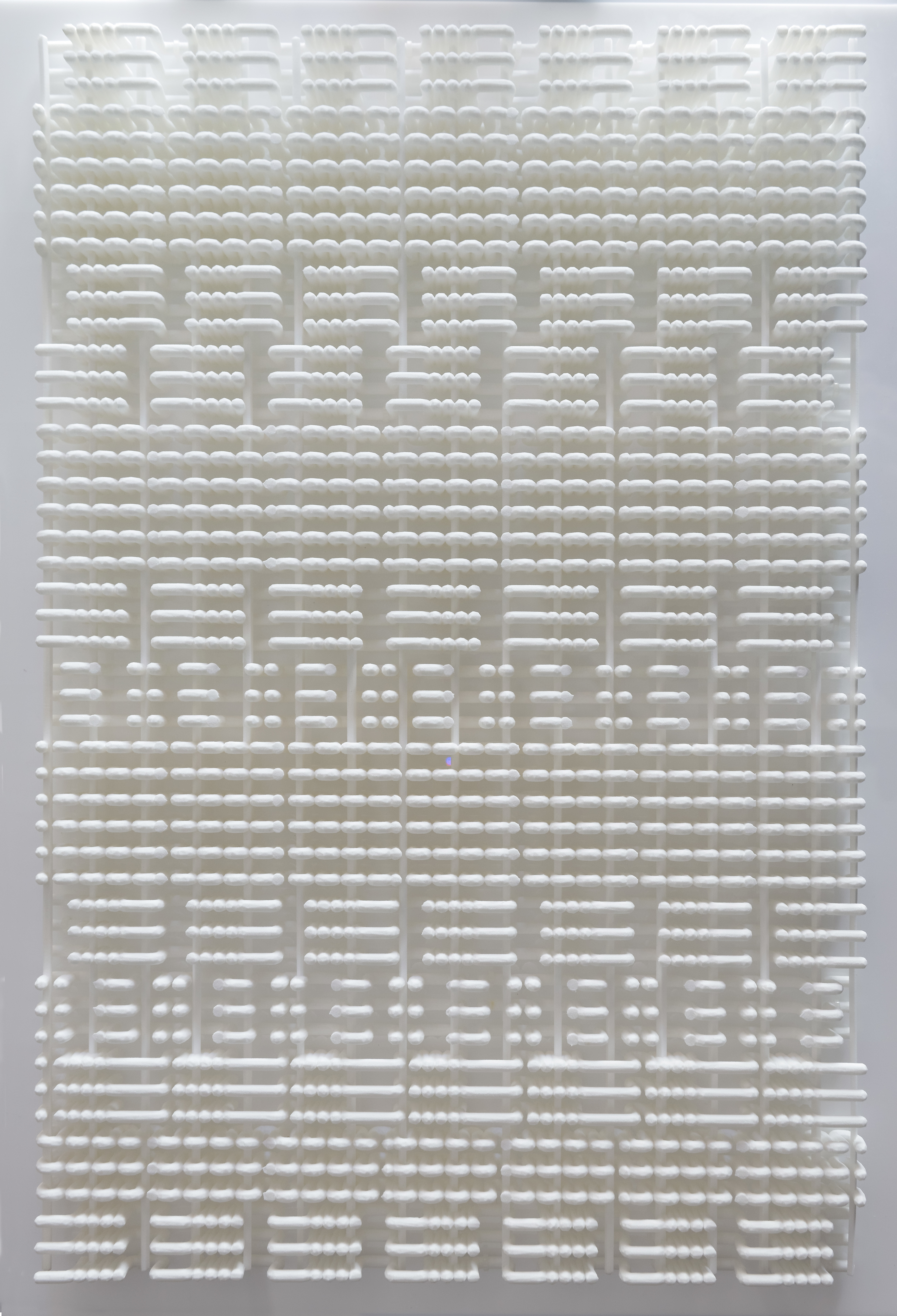

My project is focused on why fashion wants to use 3D printing. What kind of textiles can we create on a computer that we cannot create with the machines already in use for textile production? A woven structure is made up of the over-under interlacing of threads. A knit structure is a single filament looped together, creating multi-directional stretch. There is no machine out there than can transition between these, or any other structures. But it could be done on the computer. There are so many more ways the structure could be affected when generating the textile via code. The piping, or ‘thread’ could have variegated diameters, thus creating a textile that is denser in certain areas. And those areas of density could be engineered to fall on certain parts of the body. The structure would warp in the x, y, and z dimension. There are so many ways to engineer the textile to have different properties depending on use, and placement on the body.

The project that started this chain of thought- Dynamism of a Hand Waving- was the first 3D printed woven dress. I had many challenges in created the textile for the dress. I was able to create code in Grasshopper that would create a basic plain weave (over-under-over-under), and a more complex version that would allow me to import jacquard weave structures. But with the jacquard code I was limited. I could not repeat the structure, it would be adjusted to fit any size surface. A personal goal is to be able to create a repeat.

One of the greatest achievements in 3D printing technology, which doesn’t seem to have been explored much yet in fashion, is the use of multi-material printers. Multi-material printing allows for designated areas to be printed in different areas- some parts a flexible rubber, and others a stiff nylon. Or, more related to my previous research, some areas can be printed with metal, and others in a non conductive material, creating a 3D printed textile sensor. It brings even more dimension and possibilities into the textile.

As an artist whose primary focus is on smart textiles and wearable technology, I want to explore what kinds of smart material can be created with this new technology and how can it be used on the body. Is it really going to change the fashion industry? Or is it all gimmicks?

Made possible, in part, by a DCASE Grant

This project was made possible, in part, through funding from the Scholastic Art & Writing Awards Alumni Micro-Grant Program.